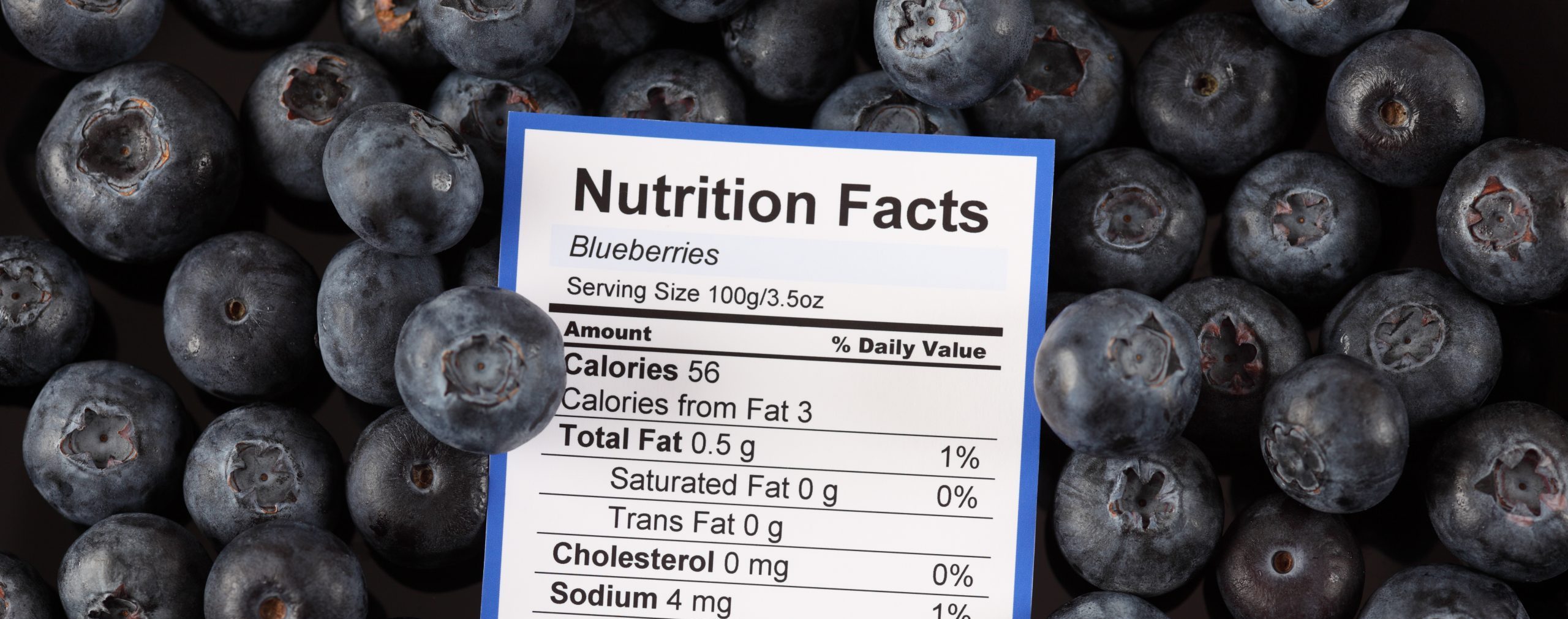

TransFresh introduces Tectrol Storage Solutions for fresh blueberries

TransFresh Corp., a wholly owned subsidiary of Chiquita Brands, has adapted its flagship technology, Tectrol Modified Atmosphere Packaging System, which is widely used to provide protection to strawberries in transit, to meet specific needs of the rapidly growing blueberry market.

“We had various shippers coming to us” asking to use the Tectrol system for pallets of blueberries to be kept in storage for two to four weeks, Rich Macleod, vice president of the TransFresh Pallet Division, said in an interview with The Produce News. “We said, ‘Sure, it sounds like a great idea to us,'” and initially used the same system that is being used for strawberries. “But what we learned is that if you are going to store product in pallet bags and store it in an effective modified atmosphere, your technology must be much more precise, much more concise and much more stable.”

Recognizing that simply using the same technology that works for strawberries in transit did not meet the needs of the blueberry industry, “we backed up and said, ‘Time out! Let’s take our blinders off,” said Macleod. So the Tectrol team took a fresh look at the technology. “As soon as we did that, we started getting a series of creative ideas from my team,” and specifically from Reilly Rhodes, TransFresh Tectrol business manager for fresh blueberries, who spearheaded the multi-year development project, as to how things could be done differently.

“It was an incredibly valuable lesson,” Macleod said.

“To develop the unique Tectrol Storage Solution for fresh blueberries, TransFresh looked more closely at storage needs versus shipping needs,” according to a TransFresh press release.

While the strawberry application required high-volume capability on the order of 300 pallets a day in a large facility, working in the range of 100 units a day in a blueberry facility would keep everybody “pretty happy,” Macleod said. “That allowed us to modify our technology.”

The “A-ha” moment, as Rhodes called it, came when the development team decided to try turning the pallet-sealing method quite literally on its head, according to the release.

Rather than pull a pallet bag over the top of the pallet and seal it with tape to a sheet of plastic placed under the stack of trays on the pallet, they tried inverting the bag and pulling it up around the pallet, then sealing it across the top, said Macleod. “As soon as we did that, our seal technology became virtually 100 percent effective.”

Once the sealing system was redesigned, “we married the redesigned seal and bag with the Apio BreatheWay technology,” Rhodes said in the release. Apio is a subsidiary of Landec Corp.

By having achieved precise control over the seal and then combining it with the predictable breathability of the BreatheWay membrane technology, “we have created a package that has a stable atmosphere” with stable, predictable levels of oxygen and carbon dioxide, Macleod said. Blueberry customers who want to store pallets of blueberries “to manage the markets now have a tool that appears to be working beyond their wildest dreams.

The development of the Tectrol Storage Solution for fresh blueberries was “a multi-year research and development,” according to the release. It resulted in “a sealed package system with adjustable oxygen transfer rates that react dynamically to changes in temperature and berry respiration for more reliable fresh blueberry storage.”

“What’s remarkable about the Tectrol Storage Solution for fresh blueberries is that the innovative zip-sealed pallet system combined with the patented breathable membrane allows just the right amount of oxygen transfer needed by the fruit, resulting in greater atmosphere control than previously possible and a virtually fool-proof packaging operation,” Macleod said in the release. “Customers who may have struggled in the past to meet the specific atmosphere needs of fresh blueberries are now finding they have a new solution available with higher consistency and a more stable atmosphere for greater storage reliability.”

Macleod further commented that customers may now have much more confidence in their storage solutions by being able to more effectively match supplies with market demand. TransFresh expects that its new storage solution can be adapted to other commodities such as fresh cherries and grapes.

“Domestic markets have sold 15 percent more blueberries this year than last and represent a fast-growing berry segment,” according to the release. “As these markets have grown, the demand for a more effective storage solution has accelerated. Because blueberries are grown in a variety of countries and districts, and varieties tend to have steep production peaks, the ability to hold blueberries in modified or controlled atmosphere conditions helps to smooth out the bumps in market supply and demand. A pallet-sized atmosphere package such as the Tectrol Storage Solution gives suppliers the flexibility to market a quality product through the peaks and valleys of the distribution system.”

08/19/2014