North American blueberry industry concerned by market disruptions as season gets underway

The coronavirus (Covid-19) pandemic has created a huge number of challenges for the North American blueberry industry over the past few weeks as it gears up for its domestic harvest season, including severe disruptions on both the supply and demand side which seem unlikely to subside in the short-term.

As well as the labor, logistical, and regulatory issues the supply chain has had to contend with, it has seen expanding market disruptions hinder its capacity to sell its blueberries. All of this has created an unprecedented difficult period for the industry.

“This is a hard time, everyone along the chain is affected, especially growers. Everyone is making their best efforts and I see a lot of empathy among folks in the industry,” said Cort Brazelton, co-CEO of Fall Creek Farm and Nursery.

“We can talk about the situation, but it’s hard to identify immediate solutions to many of the new problems, other than recognizing that this is doing damage to most businesses. And long-term, it’s doing damage to the ability of the high-value, fresh produce supply chain to deliver healthy food to consumers. Growers who are in harvest are getting particularly hurt.”

When Covid-19 became an elevated concern in North America in early March before states started to lockdown, the initial complexities for the blueberry industry were labor and logistics, as well as market instability amid widespread panic buying, he explained.

Since then, much of that has given way to concerns over moving the fruit through the channels that remain in the disrupted market.

While the almost-entire loss of foodservice channels has not been as damaging for blueberries as for other produce items due to the industry’s lower dependence on the sector, it has meant more fruit going to retail. And over recent days, retail has seen new restrictions that limit sales.

These restrictions often include lower staff numbers, one-way aisles, and a cap on how many people can enter a store at once. For instance, Walmart recently announced its stores would now allow no more than five customers for each 1,000 square feet at a given time, roughly 20% of a store’s capacity.

“That’s going to have an impact,” said Kasey Cronquist, president of the North American Blueberry Council (NABC).

“Those types of things, on how the retail is managing not just its supply chain but moreover the velocity of purchase inside the stores … are changing right now in order to try and flatten the curve. Those are the things that I think really concern us in the berry category.”

In addition to the lower traffic in the stores, Brazelton said that it seemed consumers are tending more to go with a list of shopping items and are making fewer impulse buys like high-value produce.

While there is hope that the situation will normalize as soon as possible and disruptions on the industry will be minimal, Brazelton explained there was equally concern as to how much of the spring crop can be successfully marketed for good of growers and consumers.

“There’s been a cascading of events and difficulties that all restrict everyone’s ability to operate and perform all the way down to that consumer,” he said.

Supply-side concern for blueberries

On the supply-side, social distancing policies have resulted in fewer pickers on the farms and fewer workers in the packhouses. In some cases, it has also made the logistics more complicated, with fewer drivers, increased time to market, and a slower turnaround in distribution centers.

Cronquist said that new regulations that have come through in places like California add to previous Centers for Disease Control (CDC) guidelines and have “inundated” many companies with rules on how to handle the protection of the workforce.

“Those are the things that we’re collectively trying to get in as front of as many as our industry members and stakeholders as possible to make sure that they can continue to operate in compliance with these expectations,” he said.

“The good news is that the USDA has really overly committed and performed well in making sure that the programs that our farms rely on weren’t going to be impacted in such a negative way that we weren’t going to be able to move the fruit off,” he said.

One of these is the H-2A guest worker visa program, which for a few days in March had been severely restricted but has since eased following lobbying from the agricultural sector.

“There have certainly been experiences where there have been some issues, but I think for the most part we have been very fortunate to have the labor in place and be able to prep for this season beginning now,” Cronquist said.

Frozen blueberry sales growth outpacing produce average

The first major change in that market dynamic was a colossal increase in frozen blueberry sales in March, along with a smaller but still very significant rise in fresh sales.

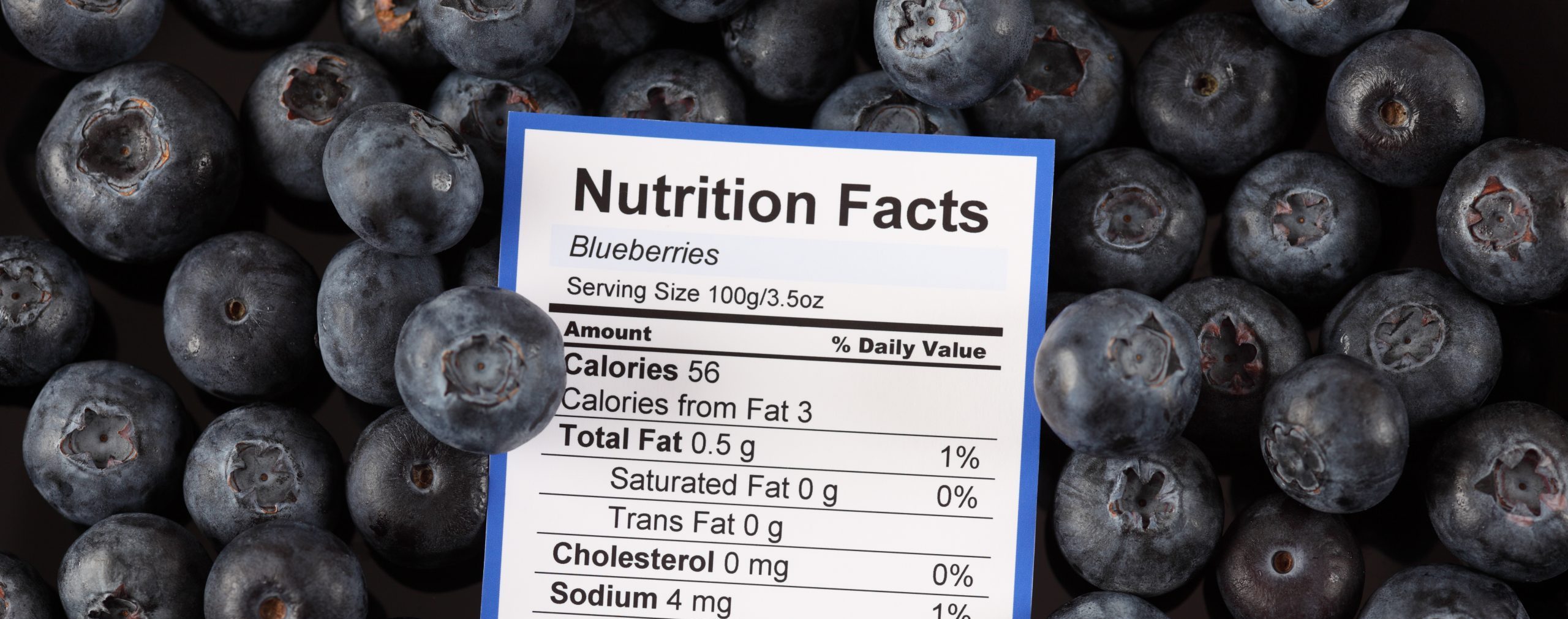

Nielsen data shows that frozen sales in the U.S. in the weeks ending March 14 and 21 were up 79% and 116% respectively year-on-year. This compares to 52% and 108% respectively for frozen produce overall.

In the fresh market, blueberry sales were up by 14% and 25% in those two weeks, against 23% and 40% for total produce.

“I think high demand on frozen is positive, however you look at it – where it’s frozen or fresh. When we can start to move frozen like we are right now it’s positive all the way around,” Cronquist said.

Brazelton explained this was because the movement of frozen blueberries helps create a floor for the fresh market.

“Frozen inventories were moved through very quickly. There are also strong indications that consumer habits change as they stay home and they’re eating food from their freezers, so that frozen fruit is getting eaten and they’re eating more fresh blueberries,” he said.

“I wouldn’t be surprised if we went into the North American summer season with some of the lowest inventories of frozen blueberries on record in the last 10 years. That is a positive note for the upcoming summer season.”

Since then the market has stabilized greatly, with total produce sales closing in on normal levels at the end of March.

Unfortunately, average pricing levels for fresh blueberries are currently lower than what they would normally be for this time of year, Brazelton said.

“The good news about blueberries is that they had a strong shelf-life, especially when it’s good product. A blueberry does last longer than raspberry, a strawberry or a blackberry,” he said. “This has been a much more difficult time for more perishable products.”

Cronquist added the blueberry category is less reliant on the foodservice sector than other produce items, and almost all of what would have been lost due to the closure of restaurants has shifted over to retail channels.

“I know some of the other produce industry folks have really been suffering through the closures of the foodservice channel,” he said.

“Our hope is that we’ll continue to invest in foodservice marketing during this time, because while we see a lot of changes obviously in the closures and the challenges that it’s created, when it comes back on we’re hoping to continue the work we’ve been putting into achieving further foodservice penetration.”

A collaborative approach

He added that the NABC and United States Highbush Blueberry Council (USHBC) have also been working hard both to let consumers know that blueberries are a safe and healthy food to consume during these times, and to understand what the industry’s challenges are in order to provide resources.

“We’ve done webinars and are providing market intelligence to everyone so they can start to adapt and evolve to what’s going to be a considerable amount of time before things start to normalize,” he said.

In addition, he said that industry collaboration currently was even more essential than normal.

“We need to continue to work closely together as an industry. Collaboration and continued effort of uniting at times like this is going to be what helps carry us through this difficulty,” he said. “We’re going to continue to work at the highest levels and at all the right tables in order to get through this together.”

Uncertainty in the European blueberry industry

Many of North America’s challenges and market dynamics are reflected in Europe, where the spring harvests are also now getting underway.

Jaime Sanchez, product manager of produce supplier SanLucar, said there are difficulties in terms of labor due to restrictions on how many people can travel in the same vehicle and due to the need to maintain a safe distance in the warehouses.

In the case of logistics, the industry faces an increase in rates because more transit days are needed to reach a destination. While the many border closures in Europe are not intended to affect essential items like food, there have inevitably been delays and disruptions.

“But the biggest challenge of all is that of uncertainty,” he said.

“It is impossible to know now what will happen when the production peak will arrive or when several seasons will coincide, which will occur in two to three weeks. But we are confident that at this period the measures of the state of alarm will be more relaxed.”

Despite the transport issues, Sánchez said there have been no problems in providing fruit in good condition and quality.

Like in the U.S., demand for blueberries experienced a spike during mid-March, and then fell two weeks later. But he said blueberry demand remains active compared to other fruits, including other berries.

“Nowadays, supply and demand are compensated, and this and this is due to the fact that we are currently working with higher grammages (300g and 500g) and thanks to the mild temperatures in the producing areas in the last two weeks, which has contributed to there not being a very fast production,” he said.

In addition, he noted that the new blueberries varieties and postharvest techniques are leading in super blueberries with a long shelf-life of over four to five weeks.

“This means, that if we keep storage in the right conditions, blueberries will keep fresh much longer than the rest of berries as strawberries, raspberries and blackberries,” he said.

13/04/2020